PA Project news

Here you can find current and past exemplary projects from our extensive product and service portfolio.

Butane process recovery plant

April 2024 (project completion) - BNT Chemicals GmbH - Bitterfeld-Wolfen

Project description:

Butane process recovery plant with two gas heat exchangers (water separator and reliquefaction), compressor unit and a cooling system including two butane store tanks.

Package of the following components and services:

- Gas/water heat exchanger Gas throughput approx. 332 kg/h or approx. 125.1 Nm³/h Gas composition: 12% iso-butane, 86% n-butane, 2% nitrogen

- Compressor unit, rated output 200 Nm³/h, medium butane

- LPG tank, nominal capacity 4850 l, usable capacity 2.1 t

- 2x piston pump unit (400 V), for suction operation, make P&A type PA-KPM-1, medium butane

- LPG tank, nominal capacity 2750 l, usable capacity 0.9 t

- Robust and reliable refrigeration machine for industrial use, cooling capacity 54 KW

- various safety fittings

- Control cabinet including PLC control for controlling the above-mentioned pumps, compressor, the two water/gas heat exchangers, 54 KW refrigeration machine, tank pressure monitoring, tank pressure limiter, tank content limit switch, temperature monitoring, compressor control, etc.

- Complete piping of the offered assemblies in Salzgitter, preparation for the safety valve blow-out lines on the central blow-out mast / gas flare

- Pressure and leak testing for the assemblies

- Compilation of material certificates and attestations

- Test run of the plant in the presence of BNT Chemicals

- HAZPOP (risk assessment for the delivered assemblies),

- 3D-Model

- Interface information for MSR technology

LPG plant with 29 t large tank

March 2024 (project completion) - Deutsche Giessdraht GmbH

Project description:

Liquefied gas plant with a 29 t underground liquefied gas tank and an electrically heated evaporator system with an output of 1920 kg/h. System classification in group B according to TRBS 3146 including a gas/air mixing system with an output of 2200 Nm³/h or 22 MW.

Consists of the following components:

- Underground LPG tank 29 t with a usable capacity of 62 m3 - corresponding to a filling quantity of almost 25 t

- Buoyancy safety system

- Corrosion protection system

- including all necessary fittings

- Tank truck unloading station with filling and pendulum hose and the necessary fittings such as quick-closing ball valves, breakaway couplings, etc.

- Railway tank wagon unloading station with filling and pendulum hose and the necessary fittings such as quick-closing ball valves, breakaway couplings, etc.

- Corken compressor unit type 691, medium propane, complete with a 17.5 KW ex-motor, separator, dirt trap, 4-way ball valve with pneumatic actuator, safety valve, including all necessary safety devices such as min. and max. pressure switches, temperature monitoring, fully piped and mounted on a stable base frame

- Safety equipment for the tank truck unloading station, tank truck operator station, rail tank waggon operator station, mobile fire extinguisher PG 50 and 4 fire extinguishers PG 12, wind direction indicator

- electrically heated evaporator system – capacity 1920 kg/h

- Gas mixing plant for propane/air – capacity 2200 Nm³/h, fully assembled in a 30' container

- Electrical control cabinet for controlling the quick-closing valves, overfill protection, remote content display, pressure monitoring, emergency stop system, evaporator system, heating system, compressed air compressor, gas mixing system, gas warning system, horn and rotating beacon, including circuit and terminal diagram, completely wired and installed in a 10' container

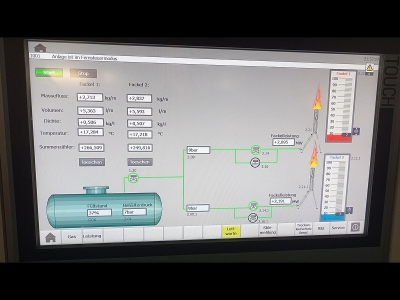

Special system for TU Braunschweig ZeBra (Center for Fire Protection)

October 2022 (project completion) - Technical University of Braunschweig

You can find a nice time-lapse video about the construction of the ZeBra HERE.

Project description:

Special system for the TU Braunschweig ZeBra (centre for fire research) for the operation of two liquid gas burners with an output of 20 MW for the calibration of a large calorimeter including the construction of a liquid gas system, piping and all safety devices.

Consisting of the following components:

- Underground liquid gas tank 2.9 t including all necessary fittings

- 2x PA flares with a power of 10 MW

- Pipelines in the test hall and in the measuring rooms

- Gas control system installed in the protective cabinet

- MSR control cabinet including PLC for controlling the solenoid valves, overfill protection, remote level indicator, control fittings, flow measurement, potential-free contacts for the control station

- Glow stick to ignite the torches

- 2x LPG hose reels

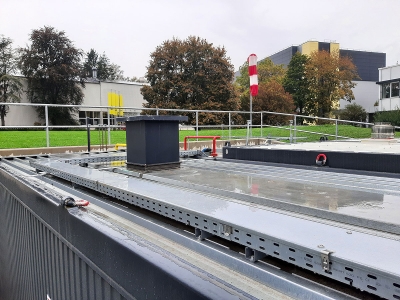

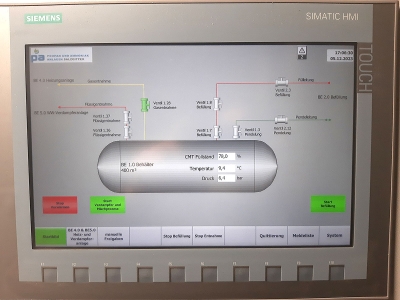

184 tons of natural gas backup solution

January 2023 (start of construction) - Klingspor AG Haiger

Project description:

Due to the war in Ukraine and the associated shortage of natural gas in Germany the company PA Propan und Ammonium Anlagen from Salzgitter is building a natural gas backup solution for Klingspor AG in Haiger. Up to 400 m³ (400,000 l) of liquid gas are stored which are made available in the event of a fault via a hot water evaporator system and an air-gas mixing system for the burners.

Consisting of the following components:

- 1 x liquid gas tank in trench storage with a nominal capacity of 400 m³, stored quantity 184 t.

- 1 x truck transfer station that can be driven over, with filling and pendulum connection including breakaway couplings and safety devices

- 1 x heating system with a 204 kW boiler installed in a 10' sea container

- 1 x WW evaporator system with a capacity of 1200 kg/h installed in a 20' sea container

- 1 x gas-air mixing system installed in the 30' sea container, output 1200 Nm³/h

- 1 x redundant pressure control line, capacity 1200 Nm³/h mixed gas

- Complete fittings and safety technology for the tanks of group C and TKW transfer station

- Ex-proof gas warning system

- Electrical MSR control of the system at the highest safety level (Simatic S7)

840.000 l liquid gas storage and withdrawal facility

September 2021 (start of construction) - Beiersdorf AG Leipzig

Project description:

As part of Beiersdorf AG's new plant construction in Leipzig we are supplying the entire liquid gas supply for the new production facility with a planned total volume of 720,000 liters.

Consisting of the following components:

- Storage container system (underground)

8 (in the expansion 11) high-capacity containers - TKW transfer station

- Booster systems

- Pipe system to the extraction houses

- Electrical control of the system

Our services:

- Engineering

- Delivery of the complete system

- Assembly incl. spilling of the tanks

- Installation of all electrical engineering

- Connection and commissioning

LNG tank system with two fuel pumps

September 2021 (project completion) - Fa. Godelmann in Fensterbach

Start of construction in July 2021

Project description:

LNG plant with a horizontal 70 m³ container and two LNG pumps

Consists of the following components:

- double-walled cryotank for minimal evaporation,

LNG capacity 25 tons, 14.5 mx ø 3.8 m,

empty weight 30 tons - cryogenic centrifugal pump for truck refueling

- two newly developed special LNG dispensers for

safe, easy and ergonomic refueling

Our services:

- Engineering

- Delivery of the system

- complete electrical engineering

- Connection of the LNG dispensers (including MID approval)

- Commissioning of the LNG plant

- Accompanying the TÜV acceptance

- Trial run

- Training of the operating staff

Fire simulation system at Stuttgart Airport

Juli 2021 (Projektabschluß). July 2021 (project completion). You can find the video of the opening ceremony HERE.

Project description:

Delivery of a 20 "gas supply container with a 2.9 t liquid gas container (installed in the container)

Consists of the following components:

- Above-ground 2.9 t container in special design

- 2 Sihi pump units as a multi-stage side channel pump

including two 5.5 KW Ex motors - 20 "technology container as standard

with required individual renovation work - Exterior paintwork in red / white according to customer specifications

- Interior painting according to customer specifications

- Remote content display with digital display of the fill level

in percent in the filling room

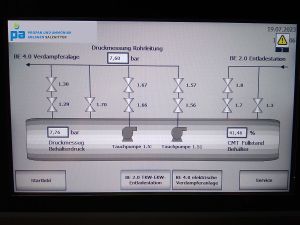

Filling and evacuation system for refrigerants

June 2021 (finished )

Project description:

Development of an explosion-proof filling and evacuation system for flammable refrigerants according to customer specifications.

For a well-known company in the field of "heat pumps and refrigerant technology", we have developed two systems especially for our customers with which flammable refrigerants can be filled and extracted.

The use of explosion-proof electronic scales ensures that the refrigerant is filled and extracted to the nearest gram.

On request, we develop special solutions for our customers that are otherwise not available on the market.

Bottle filling system in a container

May 2021 (finished )

Project description:

P&A bottle filling plant with a 2.9 t container in a 20 foot container - "turnkey" execution of the project

Consists of the following components:

- LPG storage tanks

2.9 t - liquid gas container with standard fittings - Fully automatic filling scale

3-stage SIHI side channel pump - Control cabinet for elektrical control

Complete control technology of the system with dry run protection etc. - 10 foot steel container

Floor lined with non-slip sheet steel etc.

Storage and evaporation plant (Egypt)

April 2021 (finished)

Project description:

System for the storage and evaporation of liquid gas (propane / butane) for the normal operation of a flare system.

Consists of the following components:

- 2 pieces of liquid gas storage containers

Operational switching of the containers manually

Capacity / container 6400 liters - 1 piece of hot water evaporator

Liquid gas from the storage containers will be evaporated into fuel gas

Evaporator output 300 kg / h - 1 piece of truck filling station

Connection of tank trucks for filling the liquid gas storage containers using the gas displacement method with an empty hose system